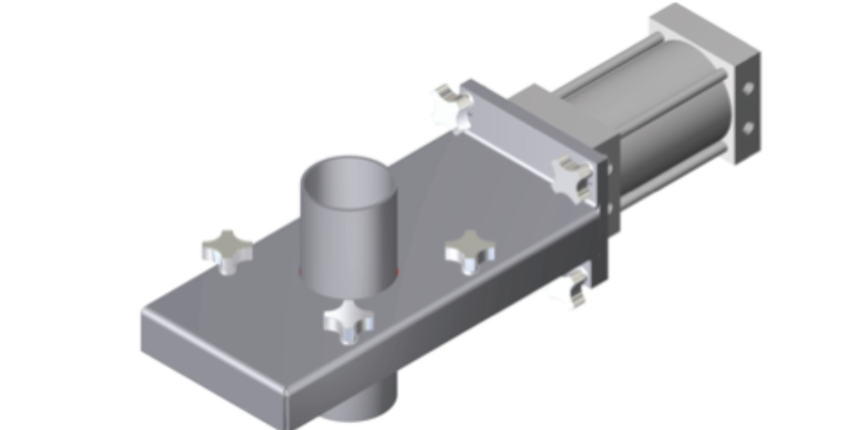

The Lorenz Series K Easy Clean Slide Gates frequently cleans the gate to prevent product contamination. They are used in a gravity feed application. The Series K Easy Clean Easy Clean Slide Gate effectively and reliably controls product flow with minimal leakage. Frequent cleaning ensures that the Easy Clean Slide Gate functions correctly. Also, the interior of the Easy Clean Slide Gate cleans by easily dismantling the gate by hand, without using tools.

The standard gate is constructed from 304 Stainless Steel (Body components, Inlet and Outlet stub and Blade) and utilizes UHMW pressure plates. 316 Stainless Steel construction is also available.

The Easy Clean Slide Gate comes in various configurations and suits most applications. Lorenz Valves are designed for dry materials only. It is not recommended to use Lorenz valves with damp or wet material. PET pressure plates substitute for standard UHMW pressure plates for applications involving sugar or other sticky materials. Teflon is for high temperature applications. For mineral based applications, Molybdenum impregnated Nylon increases wear resistance and reduce friction.

Easy Installation

The Easy Clean Slide Gate installs easily using Lorenz Bolted or Quick Release Heavy Duty Couplings. Sanitary Ferrule Connections are also available. Both connection styles allow the gate to quickly disconnect from the line, be cleaned and returned to service.

Finally, there are two actuation options for the Easy Clean: Pneumatic and Manual Push Pull. Pneumatic actuation uses a standard Lorenz Cylinder which has Aluminum Heads and body, Stainless Steel tie rods and a plated steel shaft. Internal magnets are standard. Also, they allow magnetic proximity switches to indicate valve position. Furthermore, the pneumatic Cylinder is sized to operate at, at least, 80psig.