Dry Mixing | Rigid Screws

MIXSYS is an extension of their partners at Mix Italy. MIXSYS was established with the distinct vision to successfully service their valued customers’ requirements. They achieve this through their relentless pursuit of excellence. Also they provide ‘Adaptive Mixing Technology’ suitable for all products, across all industries. Certainly, they support continued research, innovation, and development. MIXSYS is synonymous with integrity and transparency. These are the key ingredients and distinguishing markers for their business model. Furthermore, MIXSYS provides the perfect balance between cutting-edge technology, dependability, and affordability. So you can rest assured that with MIXSYS, your brand and company will be protected.

MIXSYS is strategically located in Chicago, IL. So it is centrally located in the heart of the United States. This provides unprecedented logistical support and convenience. Chicago is, of course, home to two international airports. It offers many direct flights for customer visits and on-site testing.

Process Testing

MIXSYS offers a full product test lab for complete on-site testing. Here, customers witness first hand ‘The Art of Mixing’. They have a scalable Ploughshare Test Mixer, complete with Choppers, Bombay Discharge and MixSweep Mixer Air-Purge System. In addition, MIXSYS MixPaddle is available for tests, mixer comparison and process evaluation. Additional testing provides for granulation, drying, heating, cooling and reaction from -1 to 5 bar and 0 to 200° C.

When your process requires dry mixing and blending, your Lee Process Equipment expert considers components from MIXSYS. They offer a line of dry mixers and blenders that include the following:

PLOUGHSHARE 3D MIXERS are for the most efficient mixing available.

MIXPADDLE is for paddle mixing with superior cleaning of the mixer chamber wall. It also increases efficiency and product movement during the mixing cycle.

MIX MULTI-SCREW RIBBON Blenders, includes single, double ribbon, and four screw ribbon.

SPECIALTY MIX SOLUTIONS

HEAT EXCHANGER & DRYER SYSTEMS, raise, lower or maintain a constant temperature of the product. These depend upon the process requirements and can also dry.

GRANULATORS turn and/or dry pre-mixed powders.

REACTORS achieve mixing chemical physical reactions under vacuum or pressure conditions. They do this with an external heating or cooling jacket.

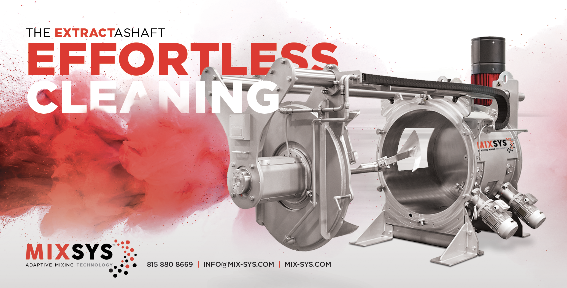

RIGID SCREW CONVEYORS

MIXSYS SCS, SCSR type screw conveyors are specifically designed. They transport cement and similar bulk solids from silos or other storage areas in concrete batching plants.

The unique design of MIXSYS maintenance-free intermediate hanger bearings and end bearing assemblies c/w splined shaft couplings are superior. Their drive units with incorporated shaft sealing unit are widely appreciated. Finally, their ball-jointed universal inlets and outlets set new standards in the industry.