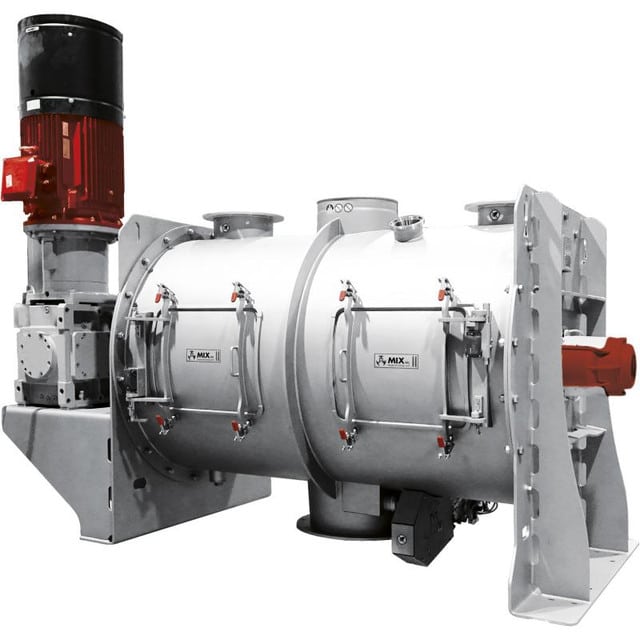

MIXSYS Batch Mixer

| Manufacturer |

|---|

The MIXSYS Batching & Mixing Stack up offers simple or sophisticated Batch Control.

Main features:

- Short mixing time

- Extremely high mixing quality

- Batches with repeatable results

- Mixing ratio 1/100,000

- Coefficient of variation (CV): ≤ 3%

- Low maintenance

Technical features:

- Batch size: from 17.2 to 7,396.5 gallons (net)

- Cylindrical mixing chamber

- Mixing tools: ploughshare / ploughshare with toothed design / Mix Paddle / Mix Paddle with toothed design

- Material of construction: carbon steel / Hardox 450 / AISI 304 / AISI 316 / AISI 316Ti

- Inspection door complete with safety electric lock

- Discharge door with round profile, building the bottom side of the mixing chamber

- Rotor shaft with turned and coaxial ends

- Rotor shaft sealing system with packing seals and wear-resistant ferrules to protect the rotor shaft, prepared for flushing with air / nitrogen

Options:

- Declaration of conformity for contact with food according to regulations 1935/2004 EC and 2023/2006 EC

- Declaration of conformity Atex II 1/3D Ex h IIIB T135°C Da/Dc (Inside Zone 20, Outside Zona 22)

- Wolfram carbide coating on mixing tools

- Liquid injection system

- Side-mounted high-speed choppers / Homogenizers

- Pneumatic sampler

- Pneumatic panel

- Heat exchanger on mixing chamber for heating / cooling processes

- Big bomb door on the whole length of the mixing chamber, to get an almost residue-free discharge in the shortest time

- Predisposition for CIP cleaning system

- Pneumatic cleaning of the mixing chamber

- Lip seal with air flushing

- Different finishes of parts in contact with product available on request.